Sustainability is increasingly becoming a central aspect of our world, particularly within the materials industry. Multiple sustainability indicators within environmental, economic, and social schemes are specifically sought to ensure sustainable production, use, reuse, and disposal of products and materials. However, the challenge lies in the quantification of these indicators and finding the best methods for measuring and reporting their impacts. Here, we will explore the most common environmental sustainability indicators in a materials selection process and how they are quantified.

As defined in the Brundtland Report in 1987, “sustainable development is development that meets the needs of the present without compromising the ability of future generations to meet their own needs.” Today, sustainability has long passed the mere association with minimising carbon and greenhouse gases. Discussions about sustainability are concerned with various matters of the environment, the economy, and the society. These are commonly known as the “three pillars of sustainability,” as they all demand consideration and proper management to ensure a sustainable future. But one question remains: How can we properly measure sustainability, quantify its impacts, and set meaningful and appropriate goals?

Well, measuring sustainability is no easy task. It is a multifaceted process that involves dozens of considerations and indicators. As more and more ambitious sustainability targets are being set by governments, organisations, and companies alike, the challenge of measuring the impacts and meeting demands has become increasingly difficult yet ever important. As stated by the United Nations Economic Commission for Europe (UNECE), “there is a widespread understanding that society needs a better statistical ‘compass’ to shift emphasis from measuring economic phenomena to measuring sustainable development.”

No matter what industry you are in, sustainable material selection has become a fundamental course of action in your work scheme. For that, NSF International developed a framework that can serve as a four-step guide into examining the sustainability metrics at hand.

- Relevance: Are you quantifying a specific sustainability concern

- Defensibility: Would a third party agree with the metric methodology and logic?

- Meaningfulness: Will these metrics guide future company and customer decisions?

- Clarity: Are the metrics effectively communicated and time bound?

As the number of indicators spanning the three dimensions of sustainability is too large to be covered in one article, we will limit our discussion here around the most common environmental indicators, without undermining the significance of the other two dimensions.

Accordingly, here are some of the key and most common environmental sustainability indicators that can go into your process of material selection.

1. Carbon footprint

The carbon footprint of a material refers to the total greenhouse gas (GHG) emissions produced throughout the different stages of the material’s lifecycle, including production, processing, use, and end-of-life. Over the whole lifespan, several GHGs can emanate, including carbon dioxide, methane, and nitrous oxide. Such gases have different heat-trapping capacities that contribute to the overall global warming phenomenon. These are measured as global warming potentials (GWPs) in units of carbon dioxide equivalents (CO2e). This allows for straightforward comparison of carbon footprints of different materials accounted for by single units.

As climate change has become one of the world’s major challenges, mitigating GHGs and adapting to climate change are now of paramount importance. Initiatives targeted at alleviating GHGs primarily depend on emission quantification, monitoring, reporting, and verification. For that, the International Organisation for Standardisation (ISO) issued the ISO 14060 family of standards that not only offers a clear and consistent approach to the measures mentioned above but also enhances the environmental integrity, credibility, and transparency of these measures.

Other indicators under the umbrella of carbon footprint include carbon reduction, carbon offset, and carbon neutrality. While carbon reduction is, as its name implies, the reduction of carbon emissions, carbon offset is that reduction made particularly to counterbalance emissions produced somewhere else. The ideal result from carbon offsetting is known as carbon neutrality, which is net zero carbon emissions.

2. Embodied energy

The embodied energy of a material is the total amount of energy consumed during the material’s cradle-to-gate time period. In other words, it is the sum of the direct and indirect energy inputs involved in resource extraction, transportation, production, processing, and delivery of the material. Embodied energy can also be defined in a way that incorporates the whole lifespan of the material (i.e., cradle-to-grave); however, such a measurement is relatively complex to calculate as it depends on the product the material was used to make. Either way, it is crucial to reduce the embodied energy of a material or product as much as possible in order to minimise its environmental impact.

Such a sustainability indicator is most commonly found around applications of building and construction, but it is also utilised in other application areas. It is expressed in units of megajoules (MJ) or gigajoules (GJ) per unit weight (kg or tonne) or per unit area (m2). In construction applications, this characterises the measurement of non-renewable energy input per unit of building material or system.

Embodied energy should not be confused with what is known as embodied carbon. Embodied carbon is, basically, the carbon footprint of the material, but it differs based on which part of the material’s lifecycle is considered. It is important to distinguish it from embodied energy as it indicates the carbon emissions involved not the energy.

3. Recycled content

Also known as recycled material input, recycled content represents the proportion of material in a product that has been redirected from the solid waste stream. This can happen in two different stages, leading to two different categories of recycled content.

- Pre-consumer recycled content: also known as post-industrial, this is when the material is redirected during manufacturing, before it reaches the consumers.

- Post-consumer recycled content (PCR): this refers to materials recycled after consumer use.

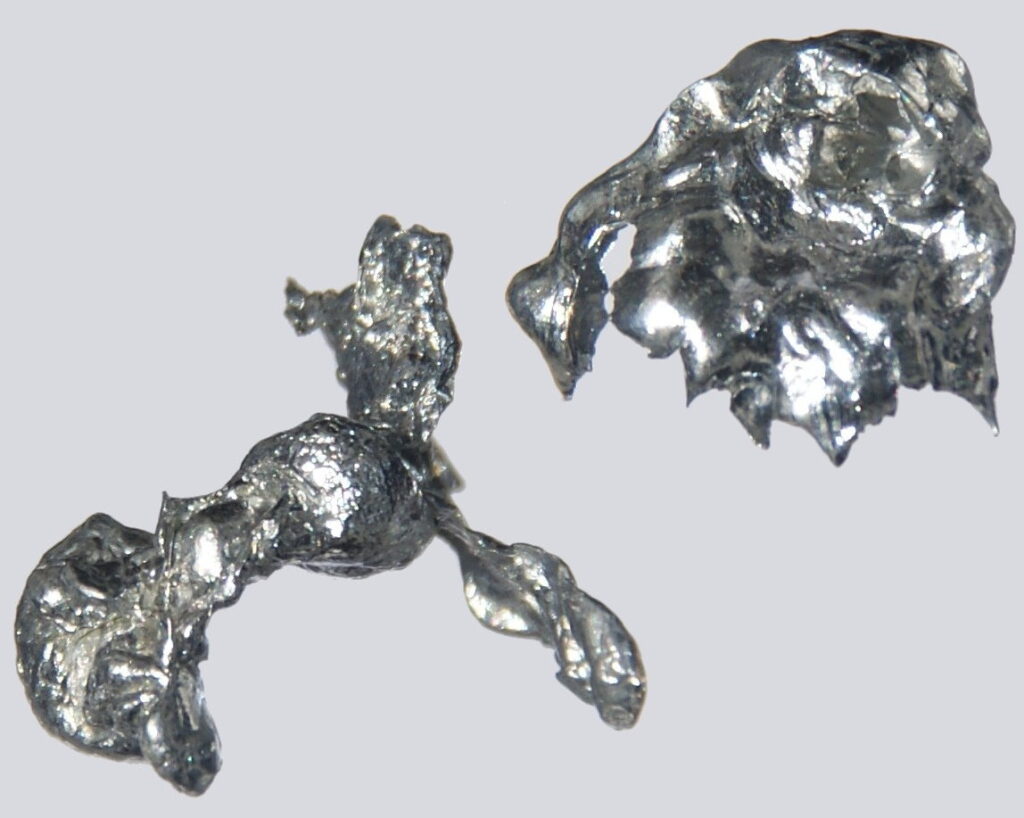

Recycled content is, generally, expressed as mass fraction in percent. Common materials that incorporate recycled content include plastics (PET, PP, HDPE, ABS), metals (aluminium, steel), and glass.

The process of recycling materials, whether they fall under post-consumer or post-industrial, plays a significant role in promoting sustainability practices and attaining sustainable materials. It effectively helps in reducing energy consumption and depletion of non-renewable resources.

4. Material recyclability

The ability of a material to be made into new products that are to be reused with little to no waste is known as material recyclability. This particular sustainability indicator has been determined as a key factor in material selection, particularly where waste disposal is resulting in dangerous environmental impacts.

Recyclability is aimed towards reducing both the input and output of a material’s lifecycle. It allows the material to join the primary production cycle again for it to be used in more ways; however, this comes at the expense of loss in material quality and value.

It is also expressed as a percentage by mass. However, it is not quite straightforward to quantify and measure it pragmatically. This is due to multiple factors affecting this indicator, from the level of complexity to sort and separate alloys and blends of materials to the degree of availability of recycling and processing settings.

Furthermore, you should bear in mind that a material derived from recycled precursors does not imply that it is recyclable. Recyclability and recycled content are two different material characteristics.

5. Other environmental indicators

The sustainability indicators explained above are not the only indicators nor are they more important than others. For the sake of brevity, here is a list of other environmental indicators that are equally taken into consideration when quantifying sustainability:

- Biodegradability

- Water usage

- Bio-based content

- Renewable energy fraction

- Material longevity

- Hazardous waste

- management

- Carbon sequestration potential

Given all these metrics, they can all be put together into what we call as an environmental sustainability index (ESI), which is a measure of the overall progress towards environmental sustainability. This composite index presents a combination of environmental, socioeconomic, and institutional indicators that have quantifiable impacts on environmental sustainability at a national level.

Read the full article in Design, Product, & Application (DPA) – June 2021 issue.

Also featured in Industry Europe, Engineering Clicks, and Engineering Specifier.