Philip K. Dick’s 1964 science fiction novel, Martian Time-Slip, imagined a human colony on Mars reliant on waterways, allotments and robots. Today, such quaint sci-fi concepts are actual scientific possibilities now that we better understand the resources that are available on the red planet. Here, Samir Jaber, engineering content writer at materials search engine Matmatch, examines how materials testing could make or break humanity’s future on Mars.

Elon Musk believes that the first sustainable city on Mars could be a reality in 20 years, with 1,000 starships to handle the logistics of the seven-month journey to the planet. On the other hand, in a recent Pew Research Centre survey carried out in June 2018, only 18% of U.S. adults believed that sending humans to Mars should be a high priority, ahead only of returning to the moon. Given our modern scientific understanding of the red planet, just how feasible is it that humans will live and thrive there during our lifetime?

To begin with, it’s unlikely that Musk’s envisioned fleet of spaceships will be overloaded with Earth materials, as it won’t be feasible to transport through space all the materials that we’ll need to live, subsist and remain safe on Mars over the long-term. Incidentally, that also includes transporting wildlife.

Instead, the design and civil engineers of the not-too-distant future will turn to Mars’ Indigenous resources to satisfy our needs. Fortunately, the red planet’s natural resources, and their possibility to foster human life, are central to why notions of populating Mars have moved from fantasy to scientific plausibility.

For one thing, Mars has carbon that can be extracted from the atmosphere and used to make plastics, rocket fuel or heating fuel. Nitrogen, hydrogen and oxygen are all biologically accessible in forms like carbon dioxide gas, nitrogen gas, and water ice and permafrost. In situ resource utilization (ISRU) equipment could be key in exploiting these resources, like subsurface water ice deposits.

Building a New Society

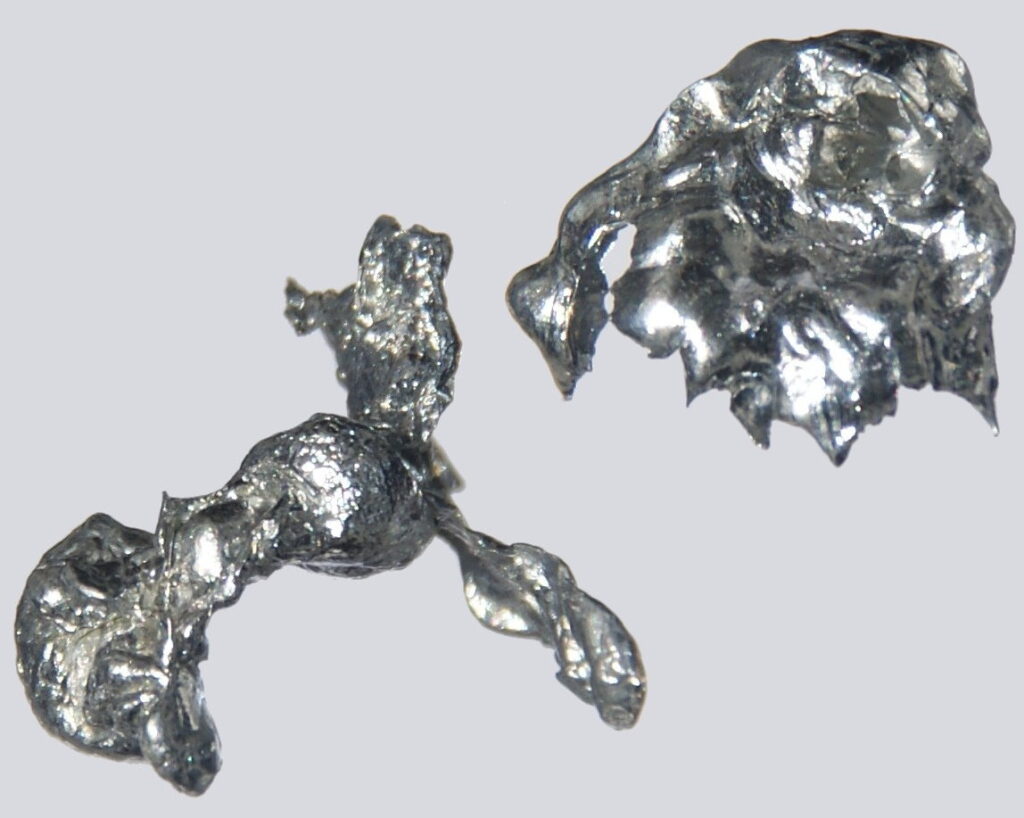

In terms of building materials, Mars’ settlers won’t be short of ceramics thanks to the ubiquity of clay-like materials in Martian soil. There are also plentiful mineral resources including iron, titanium, nickel, aluminum, sulfur, chlorine and calcium.

Silicon dioxide is the most common material on Mars, according to measurements taken by the Viking space probes, and is also a basic ingredient of glass. It is likely that glass products, including fiberglass, and structures could be constructed on Mars in much the same way as they are on Earth.

Regolith is another readily available Martian construction material. The pulverized, dusty rock — that’s mostly silicon dioxide and ferric oxide, with a fair amount of aluminum oxide, calcium oxide and sulfur oxide — has been deposited over Mars by asteroid collisions over billions of years. Researchers think that regolith could be a viable alternative for concrete.

Regolith samples have yet to be brought back to Earth. Instead, JSC Mars-1a, a regolith simulant, is a very close replica of Martian soil. It is 43.48 % silicon dioxide and 16.08% iron oxide by weight, compared with actual Martian regolith which, on average, is 45.41% silicon dioxide and 16.73% iron oxide. JSC Mars-1a has been used to explore the possibility of the use of regolith in 3D printing. Could NASA one day send robots to 3D print regolith layer-by-layer, and gradually build the cities imagined by Musk?

But how strong would Martian concrete actually be? Mars has a lot of sulfur in its soil, and molten sulfur is used to bind some concrete on Earth. Tests at Northwestern University near Chicago have mixed melted sulfur with JSC Mars-1a in a ratio of 1:3, the same recipe used for sulfur concrete on Earth. Tests of the simulated Martian concrete’s strength under compression, bending and splitting found it to be much weaker compared with concrete made using Earth sand. This was attributed to the Martian sand’s porosity. The Earth composition’s compression strength was about 30 megapascals, similar to that of cement-based concrete.

Further experiments with a 1:1 sulfur-to-sand mix compressed the mixture, broke down grains and drove out air bubbles. This resulted in a strength of 60 megapascals, which is twice as strong as concrete. Sulfur-based concrete also has quick-setting advantages, offering more immediate strength that could be advantageous for 3D printing applications.

Aside from the cement used, modular underground living will likely be the surest way to protect Mars’ settlers from cosmic radiation and intense cold. Such digging could also expose water, ice and other resources under the surface for ISRU.

Adapting the Planet

It’s impossible to deny the bare necessities, and NASA’s plans to send a crewed three-year mission to Mars in the 2030s can only happen if the astronauts have a continual food supply.

A 2016 scientific and technical information paper by NASA, “Frontier In-Situ Resource Utilization for Enabling Sustained Human Presence on Mars,” suggests that protected atmospheric environments that harness either sunlight or artificial light sources could be the answer to our food storage needs. Robots will also likely be employed — which is no stretch given that robot agriculture is firmly established here on Earth. One thing is for sure: astronauts will have to grow their own food. But how?

Here, typical science fiction concepts would include modifying or terraforming the planet’s atmosphere. In reality, humanity won’t have to go this far thanks to aerogel, the synthetic porous ultralight material. Specifically, silica aerogel — the most common type of aerogel, a good insulator and a poor conductor of heat.

The idea is that, if silica aerogel shields were placed over sufficiently icy regions of Mars’ surface, then photosynthetic life could survive there with minimal subsequent interference. Mars’ colonists would then have the capability to grow their own food with mushrooms, cyanobacteria and even insects.

Materials Testing

Alongside the efforts of NASA and SpaceX, tests of Earth-based simulants of Mars’ elements will determine whether humanity has a viable future on Mars. JSC Mars-1a, for instance, is made from basalt sourced from a volcano in Hawaii. There are a variety of Mars simulants, all based on basalt and are selected for tests based on their mineralogical properties, particle sizes and distribution, among other qualities. They include BP-1 that is made from a different variant of crushed basalt source from Flagstaff, Arizona.

For now, continued testing here on Earth will assess the viability of these materials and technologies and lead to better replicas. Ongoing tests include those by the University of California San Diego. Its research examines the relatively high concentrations of perchlorate compounds, containing chlorine, in Martian soil that render it toxic.

The studies aim to assess whether the perchlorates change the behavior of the tested materials, focusing on impurities. Perchlorates may offer a potential energy source for microorganisms, for example, and therefore potential to grow life.

Other studies, such as at the UK Centre for Astrobiology at Scotland’s University of Edinburgh, are less positive about perchlorates. One test exposed cells of the bacterium Bacillus subtilis, a common spacecraft contaminant, to perchlorates and UV radiation at levels similar to those on or near Mars’ surface.

The cells lost viability within minutes, and even more quickly in Mars-like conditions; and their life span decreased to 60 seconds when iron oxides and hydrogen peroxide, two other common components of Martian regolith, were added to the mix.

The data concluded that the probable survival of biological contaminants on Mars’ surface is low. Through the combined effects of at least three components of the Martian surface activated by surface photochemistry, the landscape of the red planet is more uninhabitable than previously thought.

A Realistic Future

It’s clear that Mars’ resources offer much potential in supporting human colonization. But it will fall to design, civil and space engineers to ensure that the fruits of these opportunities are safe, realistic, ethical and last into the long-term.

Philip K. Dick’s colonized Martian landscape of waterways, allotments and robots seems less and less like science fiction. However, rigorous materials testing of JSC Mars-1a and its variants here on Earth will be the crucial factor in determining whether humanity, and its design and civil engineers, can lay the foundations for human life on Mars.

This article was featured in Space News, Engineering Specifier, and Design, Products, & Applications.