“Great things are not done by impulse,” wrote George Eliot, “but by a series of small things brought together.” While this certainly applies to advancements in nanomaterials, used everywhere from HD televisions to aerosols, here, Samir Jaber, content writer at materials database Matmatch, explains why similar deliberation is needed to assess the technology’s unknown risks.

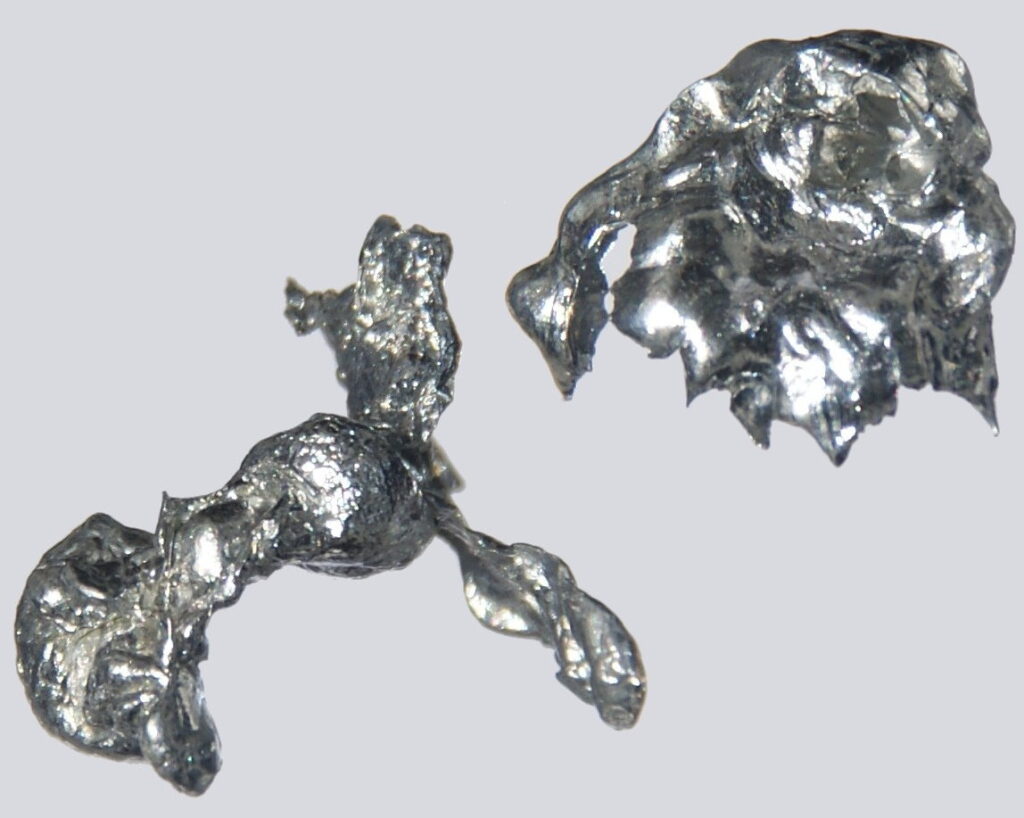

For materials scientists and design engineers, the principal qualities of nanomaterials relate to their shape, size, surface characteristics and inner structure. To give an idea of their size, nanomaterials are frequently compared to a single strand of human hair, which typically ranges in diameter from between 50 and 100 µm. A nanomaterial is hundreds and thousands of times smaller than this, with spatial dimensions of below 100 nm.

The minute size of nanomaterials is key to their existence in a variety of forms and their use in various applications. These include as solids and liquids in air, in aerosols, liquids-in-liquids as found in emulsion paints or as solids-in-liquids commonly used in sedimentary fluids. Their end-uses are just as varied as they are impressive, from next-generation computer chips and phosphors for HD televisions to insulation materials and hardened cutting tools.

Better chemistry

Besides their shape, other key features of nanomaterials include their chemical composition, physiochemical stability, crystal structure, surface area, surface energy and surface roughness. These latter properties are of particular interest as we see increasingly high requirements of the surface and interface properties in many mechanical systems.

These demands, in turn, require new designs and improvements in surface modifications and manufacturing technologies. This is where the unique mechanical properties of nanoparticles have shown real potential over the last couple of years.

Increased interest in nanoparticles has likewise seen an evolution, and many different compositions and physiochemical properties are now available.

These unique properties affect, firstly, their usability — in biomedical applications, for example — and also their toxicity. Nano-research has delved increasingly into the latter in recent times to predict the toxicity of nanomaterials. However, it is far from straightforward to find specific correlations between this data, which is often incomplete and unrelated. That also goes for matching different critical physiochemical characteristics to the materials’ potential toxicity.

Materials scientists are still studying and balancing these known and unknown qualities. These efforts have evolved significantly in recent years, in both Europe and the United States, particularly in relation to the toxicologically relevant properties of engineered nanoparticles.

This isn’t the only way that nanoparticles remain unpredictable — especially in relation to their risks.

Under the skin

The principal risks of nanomaterials relate to human health. Nano-sized particles can enter the human body via the lungs and the intestines, while penetration of the skin — though possible — is less likely. Chances of penetration depend on the particle’s size or surface properties, as well as the point of contact in the lung, intestines or skin. Their size also affects distribution within the body.

The health effects of nanomaterials still require detailed research and development, especially given the variety that is in existence today. Each nanomaterial should be treated individually in terms of their potential health risks.

Current tests to assess the safety of materials should also be applied to identifying hazardous nanoparticles — instances can include identifying increased risks of heart or lung diseases. Given the complexity of the technology, specific measures should be taken for every newly produced nanoparticle.

The onus, here, falls to the industry, legislators and risk assessors to devise low-cost tests without reducing the efficiency of these assessments.

A question of scale

In 2007, the production of nanomaterials increased in scale to thousands of tons. Aside from being an impressive engineering feat, this milestone also increased the likelihood of the materials potentially entering the environment.

There remains an almost complete lack of data on the effects of nanomaterials on the environment, whether it’s through production, manufacture or disposal. The latter evokes issues of bioaccumulation, bio-toxicity and biodegradation.

While concerns have been raised about transport and transformation of nanoparticles released into the environment, a lack of significant findings means that no definite conclusions about the toxicity of biomaterial can be drawn, at present.

To allay these concerns, it is worth noting efforts to develop the environmental friendliness of nanomaterials. This includes their use in increasing the efficiency of fuel cells and solar cells, thereby decreasing our reliance on fossil fuels in these technologies. Further to this, photoactivity demonstrated by nanomaterials indicates potential uses in bioremediation to remove contaminants and pollutants in the environment.

Despite the clear advantages of nanoparticles, further studies are being conducted into their mechanical properties; particularly with advances of characterisation techniques and new nanoparticle production methods. These studies pertain mainly to their size-dependent and material effects, and to gaining a clearer understanding of their use in specific applications.

One way to achieve this is through direct visualisations of nanoparticle behaviour on the micro, nano or even atomic scales. Another way to keep up to speed with the latest developments in nanomaterials is with a comprehensive materials database like Matmatch. To repurpose the words of George Eliot, this diminutive-yet-powerful technology must be underpinned with engineering and scientific rigour, rather than impulse.

This article was featured in Industrial News and Engineer Live.