Imagine being able to take a trip from New York to Washington, or from Amsterdam to Düsseldorf in 30 minutes? With the hyperloop, transportation might become so fast that no distance would ever be a problem. Here, Samir Jaber, content writer at materials database Matmatch, has given more insights about this futuristic transportation from a materials science perspective.

High-speed rail travel is not a new concept. One of the earliest examples was Japan’s Tokaido Shinkansen commercial service, which was established in 1964 and made it possible to reach speeds of 210 km/h. In comparison, if and when hyperloop transportation becomes a reality, it would be possible to travel in ‘capsules’ or ‘pods’ floating inside of a steel tube, free of air resistance and friction, and reach incredible speeds of up to 1,220 km/h. That is knocking on the door of the speed of sound.

Currently, Virgin Hyperloop One Systems and Hyperloop Transportation Technologies (HTT) are two of the most famous hyperloop projects in action. To study and demonstrate the benefits of maglev and vacuum tubes, Virgin Hyperloop One built a 500m ‘DevLoop’ test ring in the Nevada desert.

The problem behind it is that the vacuum tube (or vactrain) needs to be very stiff to cope with meteorological obstacles such as rain, air, heat or even earthquakes and vandalism. Also, to build such an ultra-robust infrastructure, tubes need to be very long, which can make the manufacturing process quite expensive, especially if the required materials are not widely available or do not exhibit the necessary features.

Most importantly, if a pump fails, the tube will return to a normal atmospheric pressure, which can be very dangerous for the safety of the passengers. The pumps required to generate the thrust needed for a hyperloop would be turbomolecular pumps. These are vacuum pumps that operate at high speeds to move gas molecules fast enough to create and maintain a vacuum. Maintaining a low-pressure vacuum involves the pump operating at between 20,000 and 90,000 rotations per minute, which means a slight fault could cause catastrophic pump failure.

Above the vactrain would be the standard atmospheric pressure, equating to about 10,000 kg of pressure per square metre. The biggest risk here is that even a minuscule puncture would cause air to rush into the tube at supersonic speeds, with atmospheric pressure behind it. This would cause the tubes to violently implode, with the pressure proving fatal to passengers. If a single pump’s motor were to vibrate, its high speeds would cause it to disintegrate and expel the turbine blades, which could easily puncture the tube structure and prove disastrous.

To avoid these issues and to ensure the Hyperloop’s infrastructure is safe and resistant in the long-term, the choice of material is vital.

Materials are the key

Hyperloop can revolutionise the transportation industry, but there are many elements, from the vacuum to the single electrical components, that need to meet the requirements for the full safety and efficiency of the pods. The materials used are crucial as they need to be very robust, flexible and have a reduced thermal expansion coefficient. Importantly, as many materials as possible need to be affordable and easy to find, otherwise, the entire project would have enormous costs.

Steel, for example, is a great option as it is widely used and produced with relatively low costs and high stiffness. For centuries, steel has been a prevalent material in railway projects. The most important properties of steel are great formability and durability, good tensile and yield strength, and good thermal conductivity. Furthermore, stainless steel is also resistant to corrosion, which helps keep the structure unaffected by corrosion-inducing environmental factors.

According to the Hyperloop design report by the MIT Hyperloop Team for the SpaceX Hyperloop Competition 2015-2017, the pod system was based on electrodynamic suspension systems, which can improve the dynamics of the transportation during cruise. The use of levitation magnets provides high stiffness and low damping during cruise, which means the pod would move safely without producing oscillations.

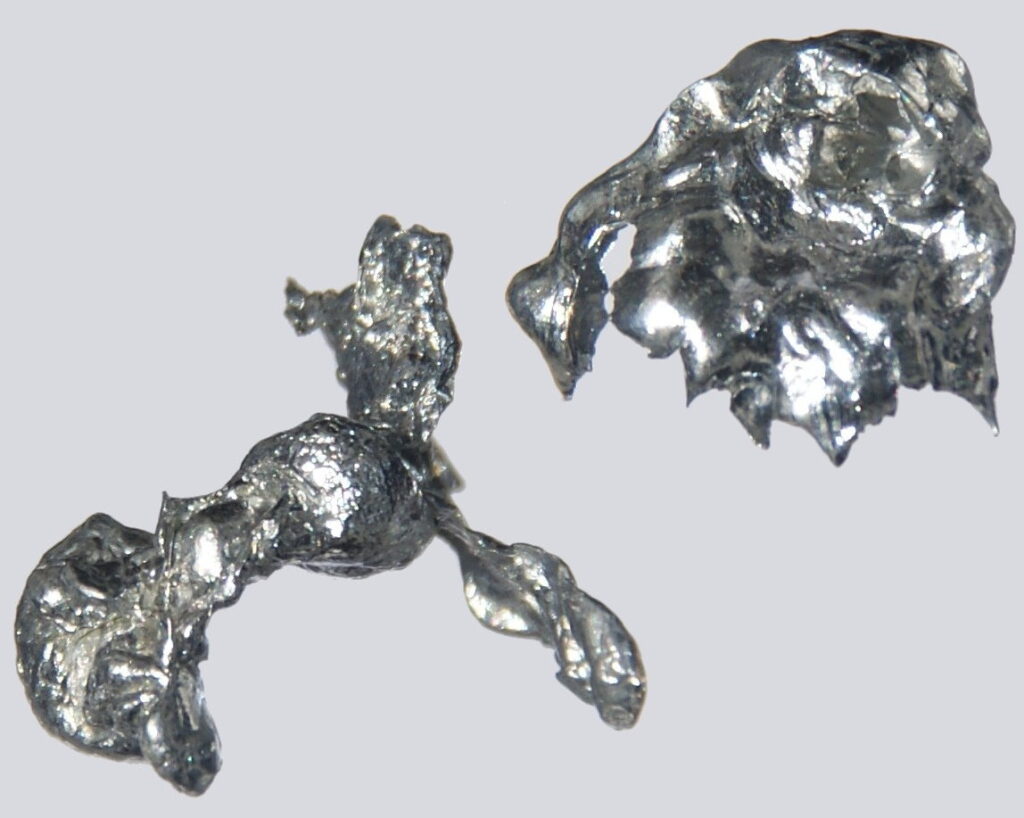

For that, they used a low-carbon steel material known as 1018 steel, which has a good thickness and is easily machinable and formable. This made it simpler to build the resistance tubes, magnet bridges, and other infrastructure parts. Low-carbon steels are the most commonly used types of carbon steel, particularly due to their low cost and high ductility, which results in their excellent machinability and weldability.

Alongside steel, composite materials, which are already used in aerospace applications and are rapidly emerging in civil structures, can be suitable for the hyperloop projects.

Using composites rather than steel has its advantages. For example, aluminium matrix composites (AMCs) are high-quality lightweight materials that are more flexible and resistant to shocks of pressure and temperature than steel. It’s also possible to use composite materials with steel, like the ultra-high-performance steel fibre reinforced concrete (UHPFRC). With these materials, hyperloop tubes would be lighter and thicker than pure steel tubes, reducing the risks of buckling and heat expansion.

Thanks to another competition in 2017 at SpaceX’s Hawthorne facility, a team of students from Delft University proved the benefits of composite materials in Hyperloop by using the composite TenCate 8020.

Delft Hyperloop’s half-scale pod was the first pod shell to be designed with carbon fibre composites. The company TenCate Advanced Composites provided the students with epoxy-based woven carbon fibre and uni-directional prepregs for manufacturing the pod’s monocoque.

TenCate 8020 was evaluated as an excellent material of choice as it provided a high stiffness-to-weight ratio. Also, the epoxy-based material had a low and flexible cure schedule (temperatures start at 70oC), offering more freedom and shape opportunities.

Despite the high costs and risks, hyperloop infrastructures can make ultra-fast, more efficient and even more sustainable transport thanks to the use of electricity. As we have seen, hyperloop transportation can be a reality. Still, it is vital that materials are chosen correctly to fulfil all the requirements, including availability and affordability, to avoid extortionate costs.

For engineers working on innovative projects as such, materials databases like Matmatch are helpful to ensure the right materials are selected. Features like Matmatch’s materials comparison tool make it easier for design engineers to compare materials properties and pick the best choice for the application.

This article was featured in Electronic Specifier, Engineer Live, and Design, Products, & Applications.